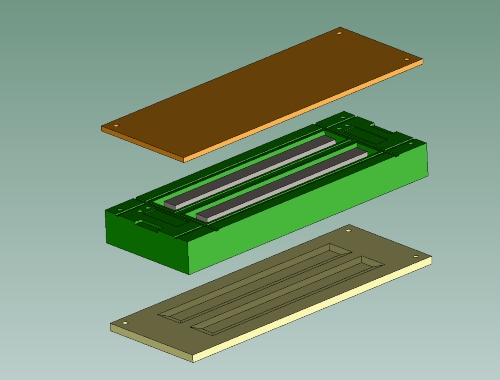

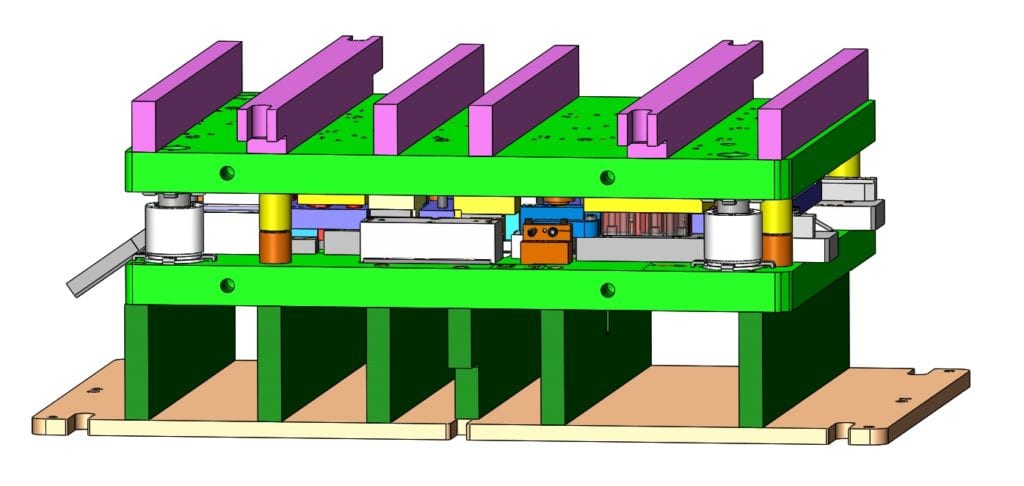

Thompson Outils Concept specializes in building small or large progressive stamping dies, primarily for the medical and automotive industries.

We’re also dedicated to keeping ahead of the competition by consistently upgrading technology and equipment to ensure that customers are satisfied with the finished product.

We mainly create dies based on part prints provided by the customer. Our versatile engineering staff and SolidWorks programs are a fundamental aspect of die building. We seek customer approval before the dies are built, and after at our facility as well as our customers facility. We also offer design assistance to help our clients overcome potential challenges.

Capabilities and Industries

We have provided progressive stamping dies to clients for over 20 years, beginning as a small, home-based business in 1996. We also underwent extensive renovations in 2014, where we added a broad variety of state-of-the-art equipment.

Our specialization is in creating tooling and dies for the automotive and medical industries, but Thompson Outils Concept also provides a broad range of end-to-end services, such as:

- Progressive and transfer dies

- CNC Machining

- Wire EDM

- Waterjet Cutting

- In-House Design and Engineering

- Production Stamping and Machining

- Prototyping

- Emergency Die Repairs

Our in-house designers and managers rely on 3D printing technology to ensure that the customer possesses proof-of-concept before any production takes place. This helps us to avoid production errors and fully understand exactly what the customer wants.

Digital optimization can simplify any complicated project from the creation of a 3D file from a 3D modeling program. The file is then uploaded, which serves as a blueprint for 3D printers. This process also offers error correction and adjustments can be made quickly and smoothly. We believe that with this 3D printing service, we are able to offer quality service as we create designs with real-time customer input in mind.

3D Printing from Thompson Outils Concept

We care about customer satisfaction, and we are committed to providing excellent, high-quality service. We are an American based company, and all of the components we produce are Made in the USA. Every project we receive is given the same level of intricate detail, regardless of size.

Every component of our stamping dies are manufactured in-house. We take pride in our work and encourage open communication with our customers.

For more information about our design, engineering, or 3D printing capabilities, please contact us or request a quote.