Regardless of your industry, Thompson Outils Concept’s wide range of equipment offers us the ability to service all your machining needs.

No matter your project specifications or industry, our capable staff and top-of-the-line tooling mean we’re always well-poised to create components that are accurate and precise.

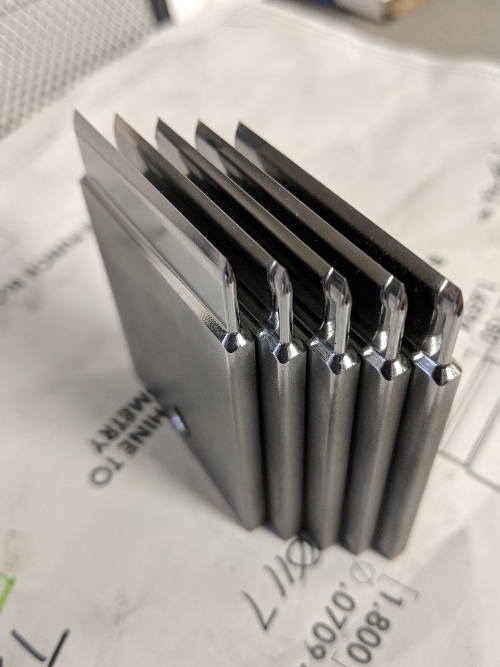

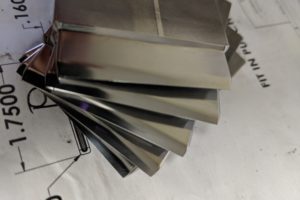

Our facility features six CNC mills with a max capacity of 120″ x 60″ x 40″. This affords us the option to machine a broad variety of components for our progressive stamping dies without sacrificing the ability to run low- to mid-volume production jobs. We can handle higher-volume projects with advanced notice and close collaboration with our team.

We also have one of the largest grinding capacities in our geographical area, with a grinding capacity of 26″ x 80″. Our facilities also feature a CNC lathe and one manual lathe. If you’re in need of turning services during your next project, be sure to mention your requirements.

Applications and Industries

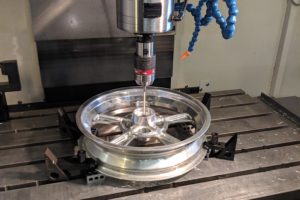

CNC machining is an integral part of the manufacturing and fabrication processes for a number of industries. At Thompson Outils Concept, our offerings focus on components intended for the automotive and automation industries. Our focus throughout the past two decades has been on building high-quality, progressive stamping dies for the automotive industry.

Within the automotive and automation sectors, CNC machining is used to create a broad variety of components, such as:

- Automated machine components

- Detail packages

- Spare details for stamping houses

- Production machining

Equipment List

Thompson Outils Concept has 20,000 square feet worth of space at our disposal. For our clients, that means access to a variety of capabilities, tooling options, and machinery. Our staff is well-equipped to tackle virtually any low-volume project thanks to our fleet of equipment. We can also handle high-volume work depending on your specifications and production schedule.

At Thompson, our equipment collection includes:

| 2 vertical milling center | YCM NSV 102A (40” x 24” x 25”), 30-tool capacity, Blum laser and probe |

|---|---|

| 1 vertical milling center | YCM DCV (120” x 60” x 40”), 60-tool capacity, Blum laser and probe |

| 1 vertical milling center | HAAS VF-OE (32” x 64” x 30”) |

| 1 vertical milling center | HAAS mini mill (20” x 40” x 25”) |

| 1 vertical milling center | OKUMA VMC (10” x 16” x 12”) |

| 1 CNC lathe | Haas, turning capacity 10”, bar feed capacity 2” |

| Wet grinder | Chevalier (26” x 80”) |

| Wet grinder | Chevalier (16” x 40”) |

| Wet grinder | Kent (12” x 24”) |

| Dry grinder | Chevalier (6” x 18”) |

| Dry grinder | Clausing (6” x 18”) |

At Thompson Outils Concept, we have more than 20 years of experience in custom tool and die services. Our 20,000-square-foot facility is home to a full range of production equipment, enabling us to provide end-to-end manufacturing services on many projects. Our team will work closely with you to ensure your project turns out perfectly.

For more information about Thompson Outils Concept and how we can support your project, please contact us or request a quote today.