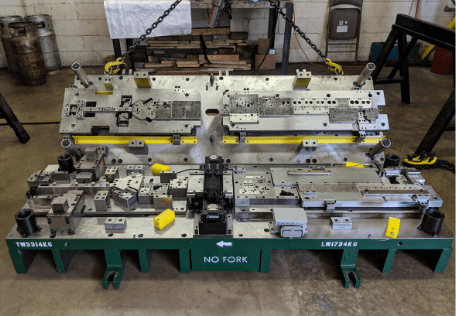

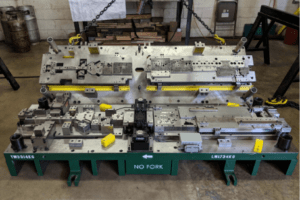

Industrial tools and dies allow manufacturers to mass-produce components in a fast, accurate, and cost-efficient manner.

For over 20 years, the technicians at Thompson Outils Concept have supported the automotive and medical industries with progressive stamping tool and die applications that facilitate the orderly production and assembly of complex devices.

With a dedicated in-house team of designers and project managers, Thompson Outils Concept routinely navigates complicated project parameters while matching or surpassing client expectations. From the initial design stages until the parts are delivered, our team works with clients to ensure their needs are met at every stage.

With a full range of services such as prototyping, emergency tool repair, and engineering changes, the technicians at Thompson Outils Concept have the capabilities and experience to keep your project on track. Throughout the tool and die fabrication process, we understand that communication is the key to developing a part that uniquely satisfies client requirements.

Capabilities at Thompson Outils Concept

Our investment in superior machining technology allows us to offer unparalleled capabilities to our industrial clients.

The manufacturing of progressive stamping dies is an integral part of the medical and automotive industries. Our processes can create custom stamping dies customized to your application.

- Our presses currently handle between 0-300 tons of pressure. This gives us the ability to try out a wide variety of tools.

All processes—including design consultations, die building, and testing—occur in-house. This allows us to control the production environment and guarantee our clients the best possible results. After component and machine building is complete, we still offer valuable services that help our clients maintain profitable operations. Our emergency repair details help to reduce downtime and preserve production schedules.

Industrial Tool and Die Services from Thompson Outils Concept

At Thompson Outils Concept, we value the client experience above all else. Our definition of success is based on the client getting exactly what they need to complete their own assembly and manufacturing processes in an efficient and cost-effective way. Regardless of the size of your company or project, every client receives the same sharp and attentive service from our designers and engineers.

We prioritize communication between our clients and our own team members. In our experience, this is the best way to resolve issues that could interfere with the timelines and delivery. Thompson Outils Concept also gives back to our local business community by using local suppliers for outsourced operations. All of our components are proudly Made in the USA.

Partner with Thompson Outils Concept on your next tool and die project. Please contact us or request a quote for more information about our capabilities.